Turn Water Threats Into Wins: Modern Drainage Solutions That Work

Water intrusion rarely starts as a crisis. It appears as puddling near entrances, on slick production floors, or as soil washout along foundations. Left unchecked, those small signs turn into safety risks, repair bills, and operational slowdowns.

Modern drainage design focuses on control rather than reaction. By guiding water with purpose-built systems, sites can stay safer, cleaner, and easier to maintain without constant fixes or guesswork.

Why Water Management Has Changed

Drainage used to mean moving water away as fast as possible. That mindset created systems that clogged pipes, overwhelmed them, and shifted problems downstream. New approaches treat water as something to manage across the entire site.

Urban development and heavier rainfall patterns have pushed engineers to rethink layouts. Systems now spread flow, reduce stress on underground piping, and limit surface disruption. Design choices aim for predictability instead of emergency response.

An engineering review highlighted how resilient drainage strategies support long-term performance by controlling runoff at multiple points rather than relying on a single outlet. That shift reduces flooding pressure and improves reliability during peak weather events.

The Role Of Linear Drainage Systems

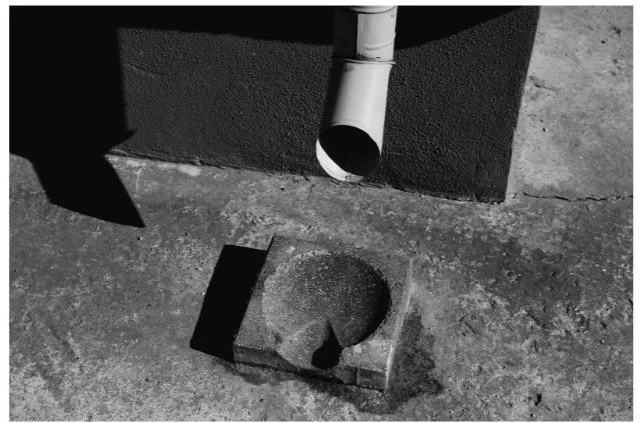

Linear drainage captures water across a continuous path instead of isolated points, which makes it well-suited for areas where runoff spreads fast. Drive lanes, production floors, plazas, and loading zones benefit from this approach since water rarely follows a single direction. By collecting flow along its natural path, linear drainage limits surface buildup before it becomes a safety concern.

Traditional floor drains rely on multiple inlets connected below ground. Linear channels reduce those connections, which lowers the number of joints that can crack, clog, or shift. Inspection becomes more straightforward, and crews spend less time tracking hidden issues beneath the surface.

Industry analysis shows long linear drains can replace dozens of point drains using far less buried pipe. That reduction simplifies installation, speeds repairs, and improves long-term access for maintenance teams.

How Slot Drains Improve Flow And Safety

Slot drains refine the linear concept by narrowing the surface opening. The channel sits below grade, with only a slim slot visible at the surface. This design supports smooth foot traffic, carts, and vehicles without raised grates.

In high-use areas, the real benefit appears during cleaning and wash-down cycles. Water enters evenly along the slot, limiting splash-back and surface pooling. The slot drain systems reduce surface clutter without disrupting flow. That balance matters in spaces where movement and cleanliness share equal priority.

Facilities that rely on frequent sanitation cycles often report faster drying times and fewer slip incidents after switching to slot-style channels. Those gains come from consistent water capture rather than higher flow speed.

Material Choices That Support Long-Term Use

Drainage performance depends on more than shape. Material selection determines how systems hold up under chemicals, temperature swings, and constant moisture.

Stainless steel remains a preferred option for demanding environments. It resists corrosion, handles aggressive cleaning agents, and maintains structural integrity under load.

Product documentation from a leading manufacturer describes how T304 and T316 stainless steel channels support sanitary design standards while delivering long service life in commercial and industrial settings. That durability reduces replacement cycles and unplanned downtime.

Designing For Maintenance

Drainage often fails when maintenance becomes difficult. Hidden traps, narrow access points, and complex assemblies slow cleaning and inspection routines.

Modern systems prioritize access. Removable baskets, open channels, and straight runs make debris removal faster. This approach keeps systems performing without specialized tools.

Key maintenance-friendly design traits include

Minimal underground pipe connections.

Smooth interior channel surfaces.

Straightforward access points for flushing.

Compatibility with automated cleaning.

These features shift maintenance from reactive to routine.

Integrating Drainage With Site Planning

Drainage performs best when considered during early site planning rather than added after problems appear. Surface slopes, paving materials, and elevation changes all shape how water travels before it reaches any channel. When these factors are aligned, runoff moves predictably and avoids collecting in high-use areas.

Linear and slot drains fit cleanly into modern layouts without disrupting visual continuity. Their low-profile design lets planners place drainage directly along natural flow paths instead of forcing water toward hidden inlets. This improves efficiency and keeps surfaces cleaner during heavy use.

When drainage reflects how people, vehicles, and equipment move through a space, trouble spots decrease. The result is steadier performance, safer surfaces, and fewer seasonal surprises.

Effective drainage turns water from a recurring problem into a managed element of the site. Modern systems combine smart geometry, durable materials, and maintenance-aware design to keep surfaces safe and operations steady.

Choosing the right solution starts with understanding flow patterns and long-term demands. With the right planning, water threats stop dictating repairs and start fitting neatly into the design.